- Home

- Products

- About Us

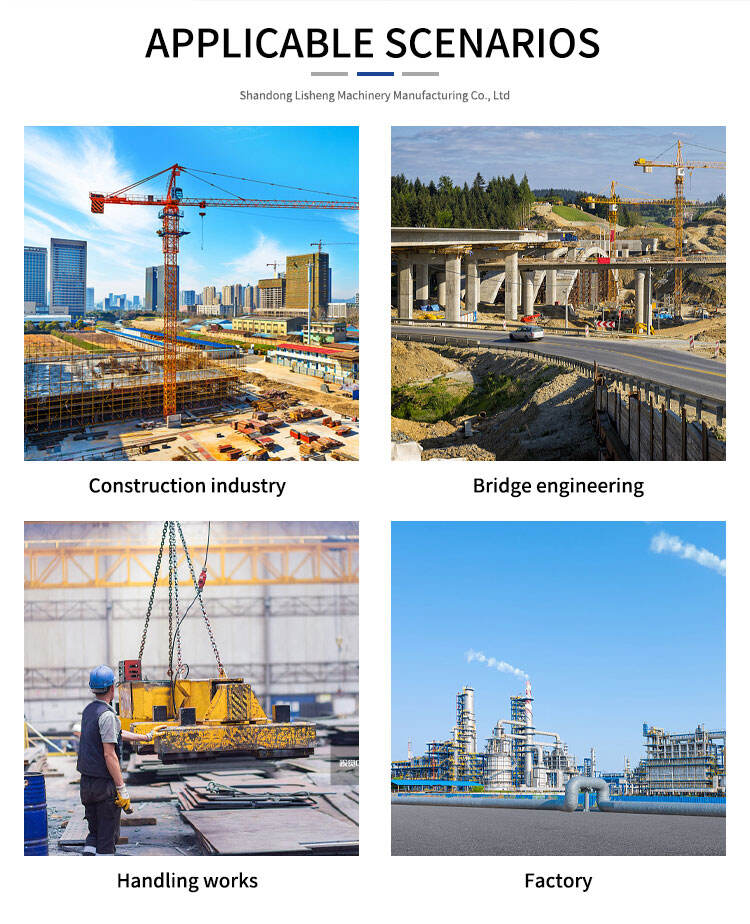

- Application

- News

- Contact Us

Presenting G80 Forged steel chain connecting link hammerlock, a great addition to your top quality lifting and rigging requirements.

Constructed with the merchandise quality materials which may be greatest, this forged steel string linking website link was created to withstand tremendous force and provide the most protection when it comes to operations. The G80 rating speaks for it self, making certain this hammerlock can up manage a great amount of to 10,400 lbs with simplicity.

The hammerlock's unique design includes a jaw strong clevis pin that locks firmly constantly in place whenever stress is used, preventing the string from sliding or coming loose during use. This included number of safety implies that your gear and workers remain protected on a regular basis.

Made of forged steel, this string website link linking extremely durable, supplying superior power and durability even yet in essentially the most demanding surroundings. Also, the LoadStar name brand is similar to quality, meaning it is possible to trust that the investment will deliver performance dependable a time long.

The G80 Forged steel chain connecting link hammerlock is incredibly versatile, appropriate for many various chains and equipment rigging. Its compact light and size ensure fat is perfect for used in tight areas or where fat limitations have been in destination.

LoadStar understands the significance of security and flexibility in top quality lifting operations, which will be the good reason why their G80 Forged steel chain connecting link hammerlock was made to fulfill and surpass the strictest industry criteria. This hammerlock was certified and tested to be utilized in an assortment wide of, including not limited to lifting, rigging, and tie-downs.

With G80 Forged steel chain connecting link hammerlock, it is possible to feel certain that your unique operations are becoming the total amount greatest of quality and security. Usually do not accept less - spend money on LoadStar's premium gear today rigging.

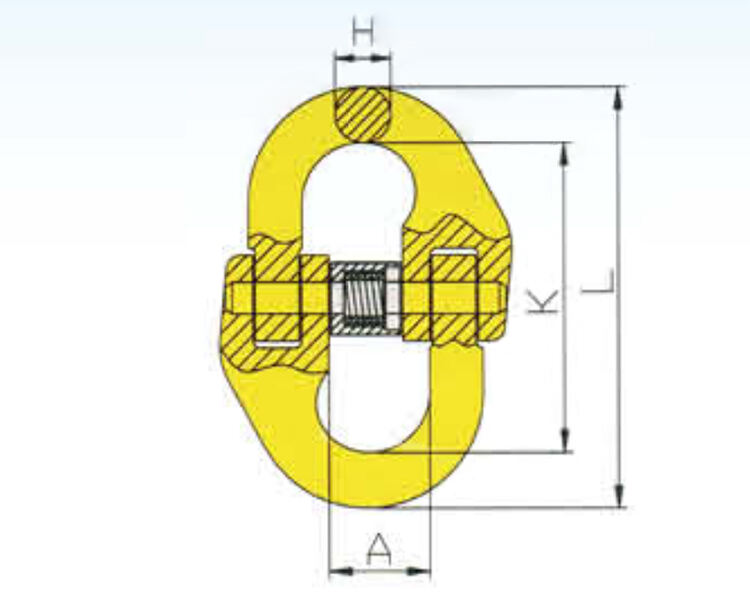

SIZE |

WEIGHT/KG |

WLL/T |

B.L/T |

A±1.5 |

B±1 |

L±2.5 |

K±2 |

H±1 |

6 |

0.08 |

1.12 |

4.48 |

15 |

7.5 |

58 |

42 |

7 |

7 |

0.145 |

1.5 |

6 |

19 |

8.5 |

71.8 |

54.8 |

8.5 |

7/8 |

0.146 |

2 |

8 |

18 |

9.5 |

79.5 |

60.5 |

8.5 |

9 |

0.16 |

2 |

8 |

19.5 |

9.5 |

79.5 |

60.5 |

8.5 |

10 |

0.30 |

3.15 |

12.6 |

25 |

12 |

90.5 |

68 |

11.5 |

13 |

0.65 |

5.3 |

21.2 |

29 |

15 |

117 |

87 |

15 |

16 |

1.15 |

8 |

32 |

34.5 |

19.8 |

148 |

108.4 |

19.8 |

18 |

1.84 |

10 |

40 |

38 |

21 |

154 |

112 |

21 |

20 |

2.1 |

12.5 |

50 |

41 |

24 |

169.5 |

121.5 |

24 |

22 |

2.87 |

15 |

60 |

48 |

26 |

193.5 |

141.5 |

26 |

26 |

4.5 |

21.2 |

84.8 |

57.5 |

31 |

220 |

158 |

30 |

32 |

8.21 |

31.5 |

126 |

67 |

38 |

281 |

205 |

37 |

Our friendly team would love to hear from you!