- Home

- Products

- About Us

- Application

- News

- Contact Us

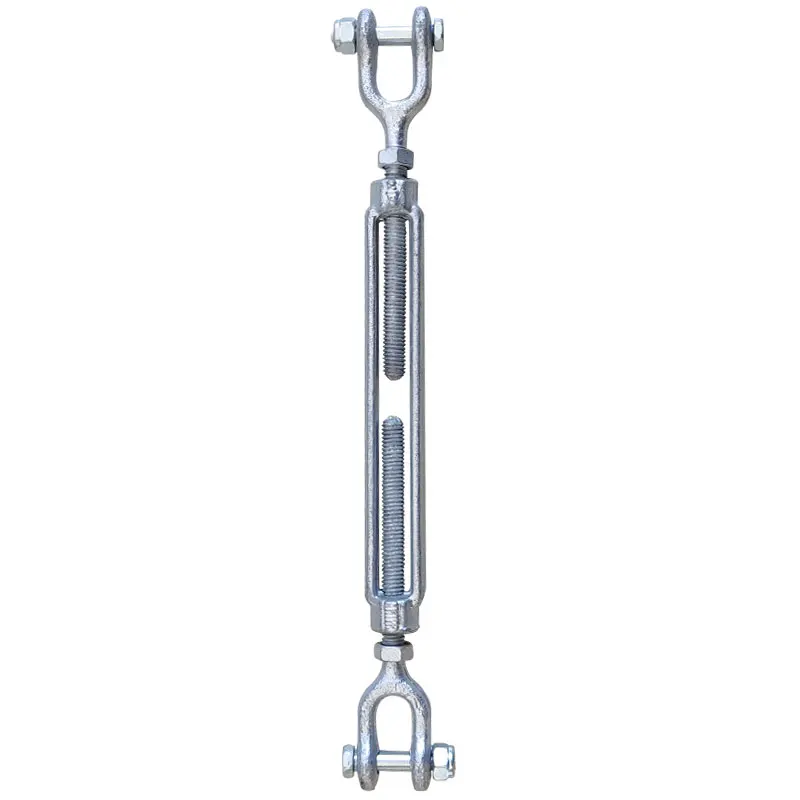

User-centered design of an industrial product is wire rope turnbuckles that are lightweight and used in numerous industries, as part of rigging and lifting operations. Their utility and flexible nature make them global necessities for random usage. To get a full freight into the world of wire rope turnbuckles: type, use, care and issues.

The diversity of wire rope turnbuckles stems from the variety of types that have been designed to perform with particular tasks in mind.

Jaw and Jaw Turnbuckle: The appear has a jaw on each opposing end, making it the ideal turnbuckle for straight pulls as they provide structural integrity in such applications.

Eye and jaw turnbuckle - One end has an eye while the other comes with a jaw, it can be used for angled pulls that make perfect to support multiple rigging configurations.

This type of turnbuckle has an eyes on the both ends, this is great for when you straight line stretch and tensioning a cable ballet in that manner which require alignment.

The wire rope turnbuckles are adaptable in their applications, being used across a variety of industries such as:

Lifting and Rigging, Used extensively for heavy load lifting and rigging activities supports safe &productivity operations.

Agriculture: These turnbuckles are used in a variety of agricultural activities such as fencing and other tasks that find application thereby making them very useful to farm operations.

Use of Marine Industry Necessary in the marine sphere for tasks such as docking, anchoring and securing watercraft to prevent accidents Duis at New York.

Use in Construction: Utilized extensively during construction to secure steel cables and ropes, reinforcing the strength of buildings as well as infrastructure for safety purposes.

Tips for Using Wire Rope Turnbuckles Correctly from the Expert User

Get expert advice on the best practices to optimize your use of wire rope turnbuckles here:

Pick the Right Kind - Always choose to turnbuckle option that meets those needs of your app precisely and keeps work at its best.

MaintenanceThrough regular inspection new warning of excessive wear and damage, to ensure the safety and normal operation.

Lubrication - Make up around screw threads with lubricant to make turnbuckle thread easy and ensure smooth functioning, which will result in higher operational efficiency.

PREVENTING OVER-TENSIONED: Take care to never over tighten a turnbuckle, doing so can cause the turnbuckle itself.to be compromised which may result in poor performance and/or failure.

Use of the Right Lifting Techniques: Apply proper lifting techniques when using wire rope turnbuckles to avoid injury and hazards as safety comes first in operations.

Top 10 Best Wire Rope Turnbuckles in the Market and Buyer Guide

Campbell 484-0.625 Heavy Duty Wire Rope Turnbuckle: Forged Steel, Hot-Dip Galvanized Finish for Corrosion Resistance; Allows You to Tension Wires with the Ability to Hold and Engage in Both Disconnecting and Connecting Activities

Crosby HG-228 Jaw & Jaw Turnbuckle Engineered for heavy-duty applications, the high-quality steel construction provides strong and dependable operation.

Wire Rope Turnbuckle - Manufactured from high-strength, low-alloy steel with hot-dipped galvanized finish for combining corrosion resistance and strength; Superstrut part number 4004

US Cargo Control Galvanized Turnbuckle - Made of high-strength steel and has a galvanized finish to prevent rusting, will hold up under lots of wear.

Mophorn 2PCS 1/2'' Wire Rope Turnbuckle: Made from high-strength carbon steel material and has a maximum working load limit of up to six thousand, six hundred pounds for multiple uses.

How To Use Wire Rope Turnbuckles: Complete Step-By-Step Guide

Know on what side to pull: Notice whether the wire has lost or gained tension and buy either style of turnbuckle.

Turnbuckle Secure Wire Rope: Make sure that each end of the turnbuckle is secured to wire ropes securely such as possibly tighten it up, so you will have a stable connection ready for safe operations.

Step 1: Loosen the Turnbuckle Begin by loosening up on turnbuckle for adjustments.

Quick Lenght Adjustment: The lengthen range of the wire rope is changed by rotating a turnbuckle clockwise or counterclockwise to met your requirements.

RETIGHTEN THE TURNBUCKLE - Turn the turnbuckle firmly around your tiedown until you have reached maximum tension on this load.

Keep an Eye Out: Perform a comprehensive examination on both the turnbuckle and wire rope to identify any wear, damage or inconsistencies that could compromise performance.

Get ready to address typical problems with wire rope turnbuckles:

Rust Prevention: Prevent rust by getting rid of what you can and some rust-resistant coating to maintain the structural integrity of the turn buckles.

Reducing Wear: Through lubricating the turnbuckle threads and operating efficiently, this will help to combat wear that may occur whilst installing / removing;

Another common diaphragm failures is due to over tensioning the unit, this will most likely lead a rupture of some sort. The other reason that we sometimes see can be tied back again down too tight on your torque equipment which leads me nicely into my next point Over-Tensioning:Over tightening = potential failure As always use the correct tension - otherwise known as adjustment levels when you alter these specifications it may result in an imbalance and poor usage therefore ultimately affects its lifespan.)

To conclude, Wire Rope Turnbuckles serve as invaluable assets when it comes to lifting and rigging operations, since they are versatile in nature while at the same time providing safety and optimum performance. Use these expert tips, choose the correct type and take the needed to care of them - you will be maximizing wire rope turnbuckle potential. Choose the best tech available - learn how to use it for maximum effect and incredibly high safety, performance, and the longevity of your projects

When you make an wire rope turnbuckle, our skilled service staff can customise products to meet your requirements and, after the completion of production our professional team is available for product quality inspection packaging, delivery and quality inspection to ensure your satisfaction.

A factory is a place for companies to manage and control the wire rope turnbuckle of production. This reduces production costs.

the company's products are high quality wire rope turnbuckle specifications designs they sell well in over 30 countries such as china iran pakistan saudi arabia the united arab emirates the united states the united kingdom australia argentina egypt

our wire rope turnbuckle have passed ce certification covering g30 g43 g70 g80 g100 and meet the standards we are committed to providing high quality products that meet international standards to meet the growing needs of our customers our products are used in engineering construction in various countries and they still maintain their strength and quality after many years of use