- Home

- Products

- About Us

- Application

- News

- Contact Us

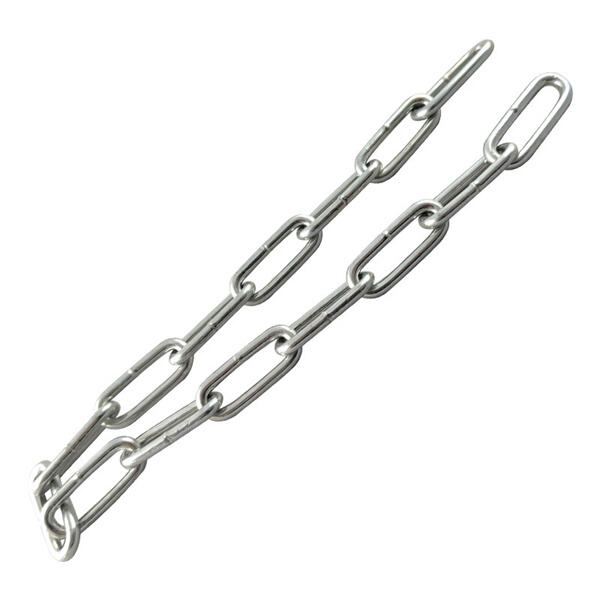

Appreciation of the dimensions of DIN 766 chain DIN 766 chain is a standard size chain, usually utilized for anchor and mooring duties to connect an anchor, windlass and chain locker

Uses: DIN766 chains are widely applied in various industries, including lifting, tightening and fastening heavy loads. DIN 766 chain is available in a wide range of diameters from 4mm to 26mm. The correct size chain plays a pivotal role to securely and safely lift or secure a load. Using too small of chain for the job can result in accidents and danger.

When selecting your LoadStar four leg wire rope sling, the one thing you need to keep the most in mind is the breaking strength of the chain and the working load limit. Breaking strength for a chain is the force at which it breaks. In contrast, the working load limit is the maximum weight a chain may handle safely under normal operating conditions. If the working load limit is exceeded the chain can break and may result in severe injury to persons or damage to property. It is essential to always work within the safe working load limits to avoid the risk of injury and to keep everyone safe.

LoadStar sling with hook are generally constructed from high-grade steel, making them strong and resistant enough to handle the lifting of heavy cargo. Furthermore, these chains come in a range of finishes to accommodate different environments and applications. Common finishes are galvanized, stainless steel, and self-colored. Galvanised chains are those that have been lathered in zinc to protect them from rust so they are perfect when used outside. Other stainless steel chains, are great for their higher rust resistance and can be used in the marine industry. Self color chains are not coated or plated so are cheaper but are not as corrosion resistant.

LoadStar slings with hooks must be inspected and maintained regularly to ensure they are safe to use. Just like any chainsaw chain, be sure to check the chain for wear, rust, or damage before each use. Pay extra attention to the links, hooks and connections, as they are the weakest links in the chain. If any damage is discovered during inspection, the chain must be removed from service and replaced or repaired. In addition to brake checks; chains must be cleaned and oiled in order to be rust free and running smooth. Correct maintenance will not only prolong the life of the chain, it also prevents costly accidents.

Compliance with DIN 766 chain specifications is essential in ensuring the safety of everyone who handles or secures heavy loads. These chain specifications are implemented to provide chains with such minimum quality, tensile strength, and endurance. WARNING: These chains should not be combined with chains that do not have these specifications, as this would lead to an accident that would result in severe injury or death to the USER or BYSTANDERS and PROPERTY damage. It is worth checking that the chain being used complies with the DIN 766 standard, replacing any chain that is not meeting these standards. By following these standards, you have confidence in your operations being safe, efficient and reliable:.

When the product is finished by a professional, they will test it for Din 766 chain specifications before packaging the product and ship it to you.

A factory is a place Din 766 chain specifications companies to control and manage the entire process of production. This helps reduce production costs.

the company's merchandise is of high quality complete specifications designs they are Din 766 chain specifications in more than 30 countries such as china iran pakistan saudi arabia the united arab emirates the united states the united kingdom australia argentina egypt

our Din 766 chain specifications have passed ce certification covering g30 g43 g70 g80 g100 and meet the standards we are committed to providing high quality products that meet international standards to meet the growing needs of our customers our products are used in engineering construction in various countries and they still maintain their strength and quality after many years of use