- Home

- Products

- About Us

- Application

- News

- Contact Us

LoadStar

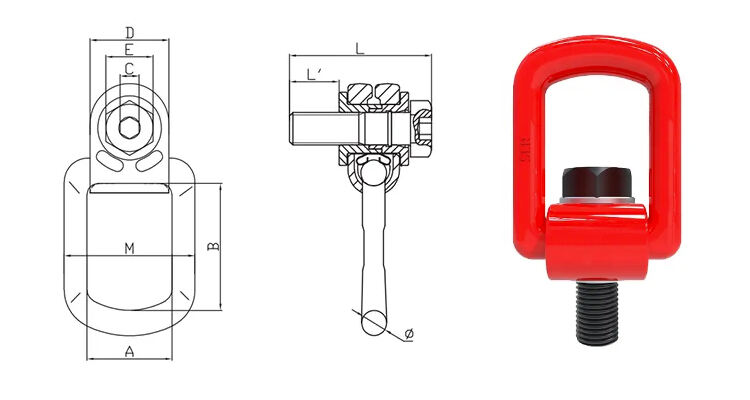

G80 alloy steel powder coated swivel hoist screw rings could be the perfect item for people attempting to put in a bit of durability and flexibility with their heavy-lifting equipment. Made from high-quality G80 alloy metal, this screw swivel is hoist are created to handle probably the most demanding lots with simplicity.

Each one of these LoadStar screw swivels is hoist was covered having a distinctive powder layer offering you yet another layer of secure deposit against typical damage. for commercial applications or heavy-duty lifting tasks, you can trust that these swivel hoist screw rings will withstand the test of that time period whether you’re making utilization of them.

For their swivel functionality, these G80 alloy steel powder coated swivel hoist screw rings are versatile and therefore could be properly used in a variety of various applications. They are perfect for usage with cranes, pulleys, other lifting gear, allowing you to easily and quickly replace the real way your load is transferring.

Among the standout top options that come with these screw hoists is their screw-on design. You might be permitted by this design to quickly and firmly connect them to your lifting gear, making your lots securely take place constantly in place. These swivel hoist screw rings are up to the work whether you need to raise hefty equipment, construction gear, or other hefty lots.

At LoadStar, we pride ourselves on producing products top-quality are made to meet up because of the requirements of your clients. These G80 alloy steel powder coated swivel screw hoist are not any exclusion. Everyone is thoroughly tested to make in order to be that it fulfills our strict quality criteria that you’re obtaining an item developed to final.

Features:

*Forged super alloy steel- Quenched and Tempered

*Breakage test

*100% magnaflux crack detection

| M8 | 0.36 | 0.3 | 1.2 | 10-15 | 35 | 52.5 | 6 | 30 | 13 | 45 | 46 | 10.4 | 14 |

| M8×76 | 0.39 | 0.3 | 1.2 | 10-15 | 35 | 52.5 | 6 | 30 | 13 | 45 | 46 | 76 | 14 |

| M10 | 0.38 | 0.63 | 2.52 | 10-15 | 35 | 52.5 | 6 | 30 | 17 | 45 | 52 | 16 | 14 |

| M10×96 | 0.43 | 0.63 | 2.52 | 10-15 | 35 | 52.5 | 6 | 30 | 17 | 45 | 52 | 96 | 14 |

| M12 | 0.71 | 1 | 4 | 10-15 | 40 | 54 | 8 | 36 | 19 | 68 | 62 | 18 | 18 |

| M12×114 | 0.8 | 1 | 4 | 10-15 | 40 | 54 | 8 | 36 | 19 | 68 | 158 | 114 | 18 |

| M14 | 0.72 | 1.2 | 4.8 | 20-30 | 40 | 54 | 8 | 36 | 19 | 68 | 66 | 21 | 18 |

| M14×140 | 0.86 | 1.2 | 4.8 | 20-30 | 40 | 54 | 10 | 36 | 22 | 68 | 185 | 140 | 18 |

| M16 | 0.74 | 1.5 | 6 | 20-30 | 40 | 54 | 8 | 36 | 19 | 68 | 70 | 24 | 18 |

| M16×30 | 0.74 | 1.5 | 6 | 20-30 | 40 | 54 | 8 | 36 | 19 | 68 | 70 | 30 | 18 |

| M16×40 | 0.75 | 1.5 | 6 | 20-30 | 40 | 54 | 8 | 36 | 19 | 68 | 70 | 40 | 18 |

| M16×100 | 0.85 | 1.5 | 6 | 20-30 | 40 | 54 | 10 | 36 | 24 | 68 | 146 | 100 | 18 |

♦ Notes ♦

1) Before each use, the operator must perform a safety inspection on the sling and use it only after being qualified;

2) The sling must be inspected regularly by professionals (trained qualified personnel) every month;

3) If it is found that the dimensional wear of the sling is greater than 5% of the original size, it must be replaced in time;

4) If it is found that the amount of dimensional deformation exceeds 3% of the original size, it must be replaced in time to ensure safety.

Our friendly team would love to hear from you!