- Home

- Products

- About Us

- Application

- News

- Contact Us

LoadStar

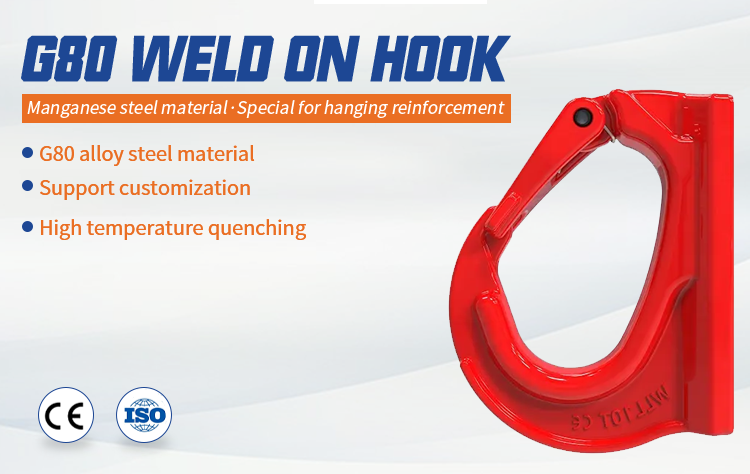

Launching Drop forged Grade 80 Weld-On Hooks for Lifting Connecting, a product designed to make lifting and linking lots hefty simple. These hooks are perfect for those that end up buying dependable and solution durable their heavy-duty lifting requirements.

The hooks are constructed with Grade 80 metal, understood for the energy and durability. The LoadStar product is specifically meant to withstand hefty lots and conditions which may be extreme. The hooks are fall forged, a process that needs warming the metal into form until it truly is red-hot then hammering it. This process leads to a hook both durable and strong.

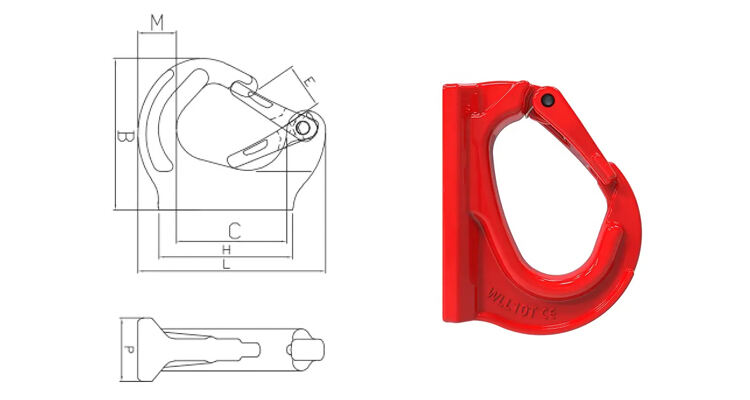

The Drop forged Grade 80 Weld-On Hooks for Lifting Connecting come in a number of sizes and capabilities, including 1/4 inches to at least one inches. The hooks can be for sale in various designs, including clevis, eye, and latch hooks. This variety helps you to make that there is a hook readily available for any application.

Installing of this hook is straightforward, since they will be created to be welded straight from the lifting unit or load. This ensures a connection and secure dependable any risk of strain and the lifting unit. The hooks are made to be simple to use, having a latch easy attention exposed and closed easily and quickly.

The Drop forged Grade 80 Weld-On Hooks for Lifting Connecting are perfect for many different applications, including construction, production, and transport. These hooks are well suited for raising lots example equipment, building materials, and automobiles.

These hooks are beautifully made with security in your head with their durability and strength. The Grade 80 steel implies that the hooks can properly help lots being hefty while the latch or attention helps you to make sure the strain is still secure during lifting and transportation.

Features:

*Forged super alloy steel- Quenched and Tempered

*Breakage test

*100% magnaflux crack detection

| ITEM NO. | WEIGHT(Kg) | WLL(T) | B.L(T) | B±1.5 | C±1.2 | E±0.5 | H±2 | M±1 | P±1 | L±2 |

| 1.0T | 0.49 | 1 | 5 | 77.6 | 61.3 | 25 | 93 | 23 | 25 | 101.6 |

| 2.0T | 0.87 | 2 | 10 | 92 | 67 | 28 | 81 | 23.4 | 34 | 114 |

| 3.0T | 1.13 | 3 | 15 | 106 | 73.5 | 30 | 116 | 30.5 | 36 | 129 |

| 5.0T | 2.5 | 5 | 25 | 133 | 94 | 39 | 159 | 44 | 43.5 | 171 |

| 8.0T | 3.26 | 8 | 40 | 137 | 94 | 36 | 159 | 44 | 51 | 177 |

| 10T | 5.2 | 10 | 50 | 170 | 135 | 48 | 194 | 54.7 | 53 | 223 |

♦ Notes ♦

1) Before each use, the operator must perform a safety inspection on the sling and use it only after being qualified;

2) The sling must be inspected regularly by professionals (trained qualified personnel) every month;

3) If it is found that the dimensional wear of the sling is greater than 5% of the original size, it must be replaced in time;

4) If it is found that the amount of dimensional deformation exceeds 3% of the original size, it must be replaced in time to ensure safety.

Shandong Lisheng Machinery Co.,Ltd.is a new generation enterprise committed to the hardware industry.Located in Jining,Shandong Province,the hometown of Confucius and Mencius. The company is a professional hardware supporting enterprise integrating design,research and development,production and sales.The main products are chains and wire ropes and their accessories:shackles,turnbuckles,clips,loops,spring hooks and other forged parts And castings,and accept drawings and samples for processing.

Our friendly team would love to hear from you!