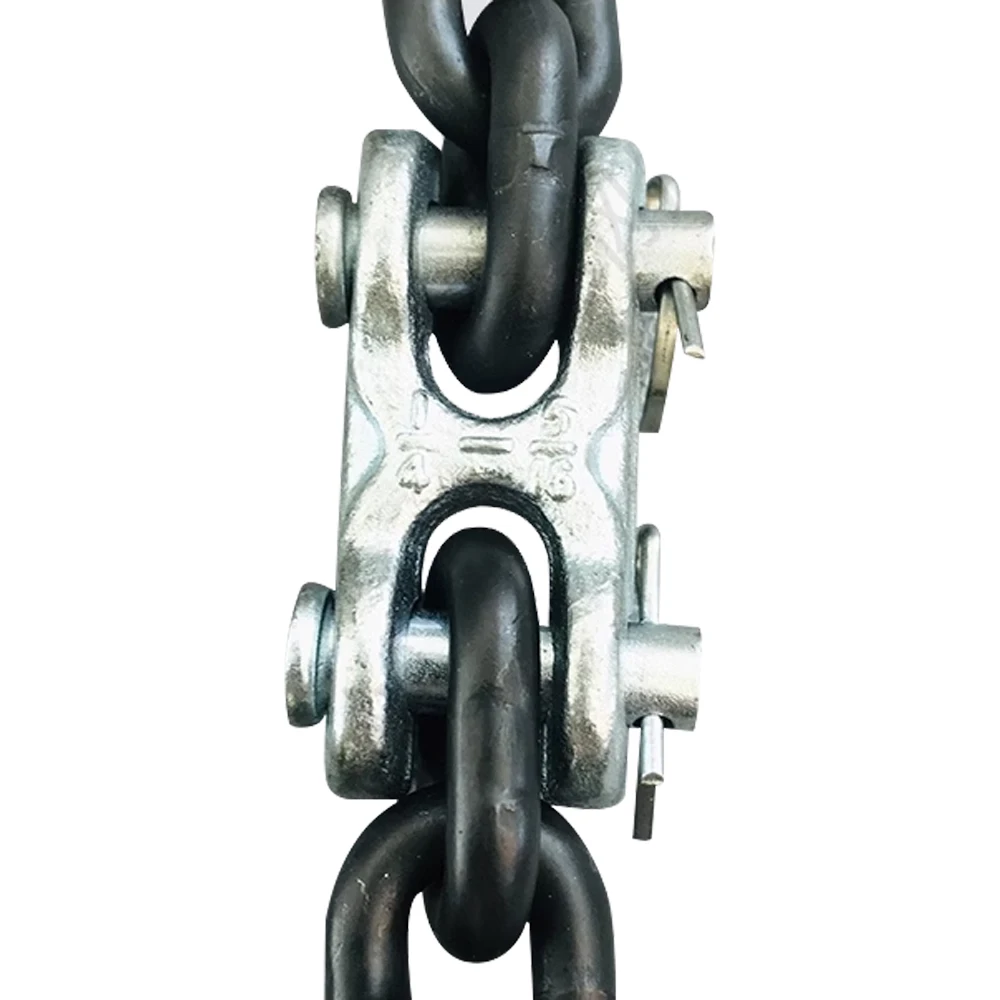

امنیت با قفل نوع D: بررسی و نگهداری

وقتی از قفلهای D استفاده میکنید، این موضوع علاوه بر سایر اقدامات ایمنی کمک میکند تا بازرسیها به درستی انجام شوند و به موقع انجام گیرند. قبل از جاسازی قفل، آن را بررسی کنید، مانند شکستگی، خوردگی یا تغییر شکل. مطمئن شوید که پین کاملاً نشسته است و هیچ دندانههای متقاطع وجود ندارد. پس از چند جلسه راندن چهار چرخی، آب شور و خاک ممکن است سریعاً قفل شما را از داخل مصرف کنند، بنابراین باید همه چیزها را تمیز کنیم. ذخیرهسازی صحیح (خشک و دور از رطوبت) نیز کمک میکند تا قفلهای شما بدون خوردگی باقی بمانند!

برای کمک به شما در تعیین اینکه آیا قفلهای نوع D مناسب کاربرد شما هستند یا نه، لیستی از مزایا و معایب رایج ارائه میدهیم.

قفلهای D به صورت گسترده استفاده میشوند و جهان وسیع وب یک شواهد این موضوع است که با نمایش هزاران سایت، مشتریان برای آنها جذب میکند. مقابلهای سنتی شاید بسیار مورد توجه قرار نگیرند، اما بله، اگر قوت نهایی و طول عمر بهترین بین تمام انواع را میخواهید؛ از این قفلهای سنگین نوع D برای مدیریت وزنهای سنگینتر و مقاومت در برابر شرایط محیطی استفاده کنید. با این حال، این موضوع نیز میتواند یک دلیل ابهام باشد اگر نیاز به راحتی حمل و نقل و حرکت دارید زیرا این فیلترها از جنس سنگینتر هستند. بنابراین باید به خاطر داشته باشید که این قفلها بین انواع مختلف دیگری از قفلها وجود دارند و نوع D به دلیل وجود این تنوع موجود است.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SL

SL

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

HY

HY

AZ

AZ

BN

BN

SO

SO

KK

KK